Repeat Length.

These are two simple words, but so many factors can play havoc with how those two words measure up. The Dynaview III Print Repeat Length Monitor measures repeat length on-the-fly, while your job is running. Your press operator will know immediately if the print repeat length goes out of the targeted preset range.

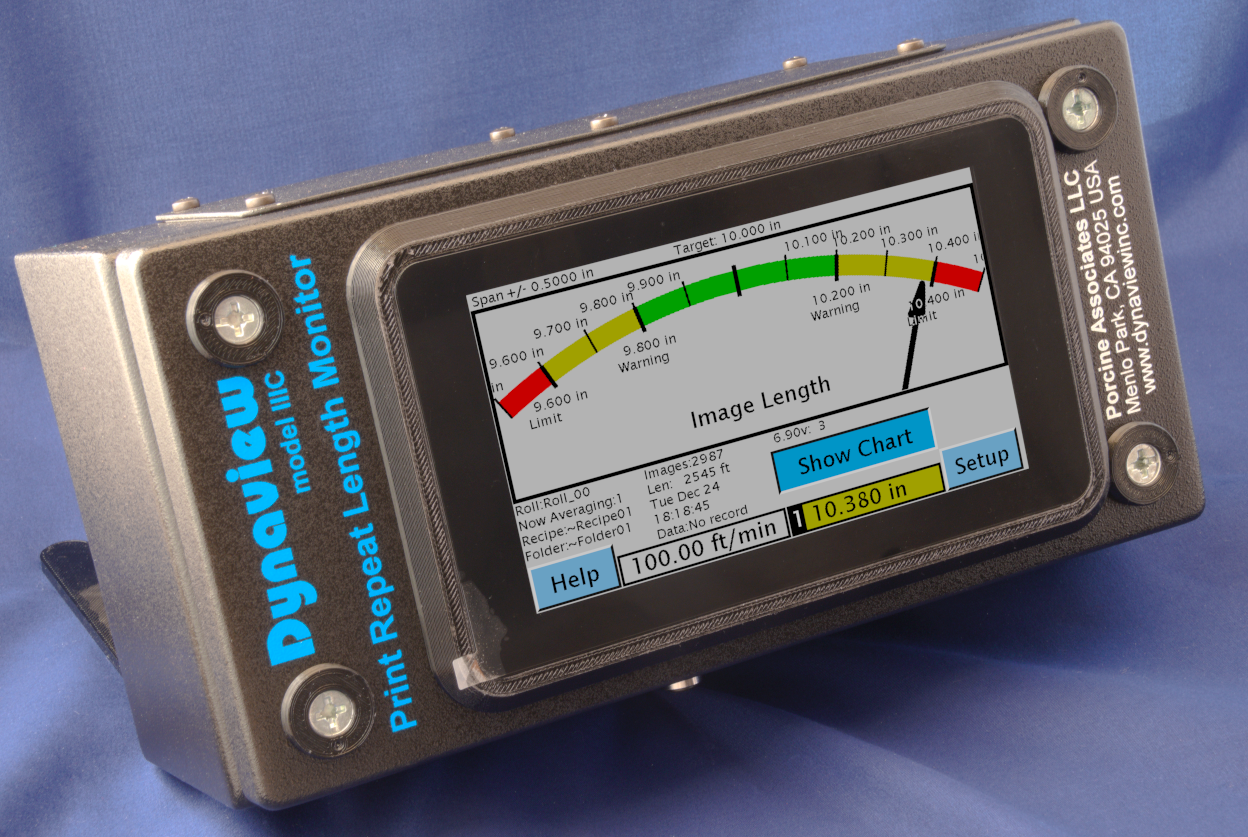

Under operator control, the large color screen displays either a meter-like moving pointer or a chart of recent length deviation from target. The chart screen shows a real-time chart (default) or an historical data chart extending back about an hour. Both displays show visual and text depictions of both the warning and limit settings and the target repeat length. In addition, both show the total footage run on the present roll, the “Recipe” in use, any averaging being used, and the current time and date. Discretionary warning alarms can be set to sound or appear if the repeat length goes out of your target range.

The Dynaview III Print Repeat Length Monitor will pay for itself in just a short time with decreased waste and improved production schedules. You’ll have significantly fewer reruns, reduced returned freight costs and improved customer relationships.

- Easy To Use

The compact backlit LCD monitor installs at the operator station with the mark sensor and pulse tachometer mounting at the web. There is no separate keyboard. The touch-screen monitor displays full color. - Touch-Screen Job Retrieval

It is possible to store more than 9,000 different job setups at one time, making it easy to change jobs at any time. Setups (recipes) are arranged in named folders, with up to 99 setups per folder. No lengthy training is required. All setup parameters are menu driven with several display choices available. Two levels of built-in password protection are also included.

- Per-roll report generation

Graphic or text reports can be generated for each roll of material processed. Several sampling schemes are supported. Reports can be printed, copied to an internal or external USB drive, and made available via a TCP/IP Ethernet network.

- Integrates with your factory-floor information system

Optionally communicates with your factory automation system via Modbus TCP or OPC UA. Dynaview exposes all it’s sensor data plus a lot more. It will even remote it’s recipe management via Modbus if desired. - It’s So Affordable

Have you ever run a roll, sent samples to the lab, and then found out the whole job was run out of spec? With the Dynaview III, your production people will know right now, as the job is running, that correct repeat length parameters have been maintained – not after the job has run or been shipped to your customer.

Dynaview I/O panel